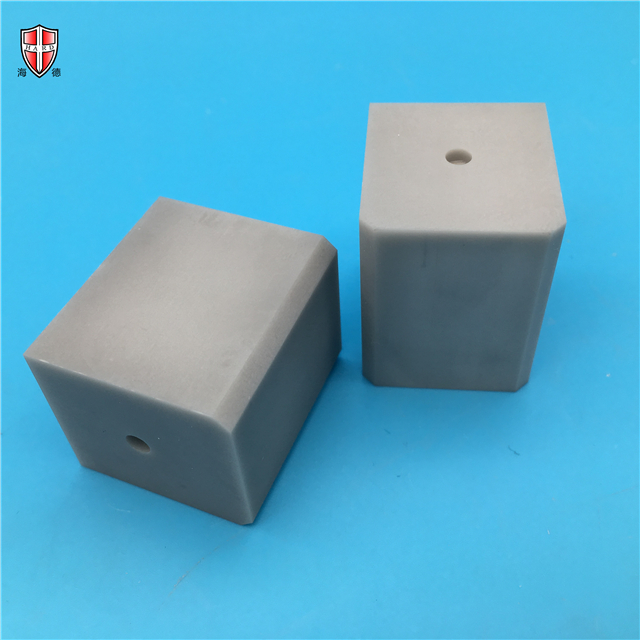

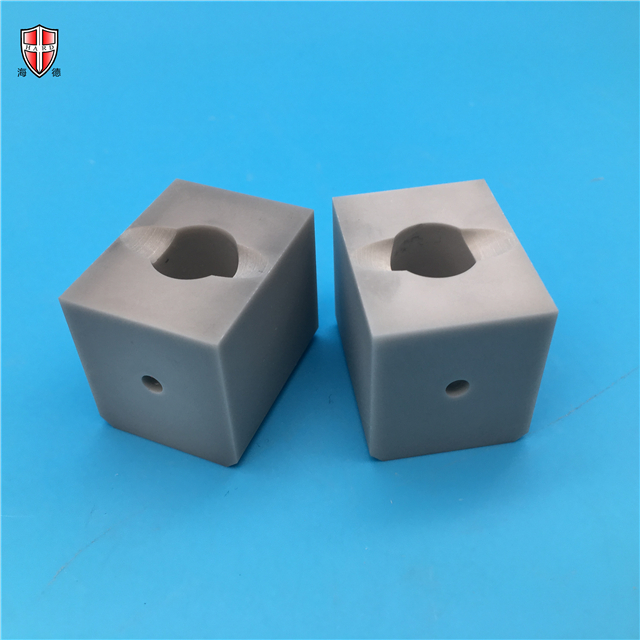

isostatic press moulding aluminum niride ceramics

Reputation depends on quality, quality comes from Hard!

Aluninum Nitride Ceramic:

Aluminum nitride ceramic processing area: the processing area of stainless steel parts should be relatively fixed. The platform of the processing area should take protective measures, such Zirconia Ceramic Sleeve as laying rubber mats. When processing stainless steel parts, damage to the protective layer on the surface of the stainless steel parts should be avoided. Chloride ions are widespread, such as salt/sweat traces/sea water/sea breeze/soil and so on. Stainless steel corrodes quickly in the presence of chloride ions, even more than ordinary low carbon steel. Therefore, there are requirements for the use environment of stainless steel, and it needs to be wiped frequently to remove dust and keep it clean and dry. (In this way, you can give him an "improper use".) There is an example in the United States: a company uses an oak container to hold a solution containing chloride ions. The container has been used for nearly a hundred years, and it was planned to be replaced. Because the oak material is not modern enough, the container leaked due to corrosion 16 days after the replacement of stainless steel. The alloying elements are not dissolved into the matrix, resulting in low alloy content of the matrix structure and poor corrosion resistance. This material without titanium and niobium has a tendency to intergranular corrosion. Adding titanium and niobium, Machinable Ceramic Bushing together Macor Ceramics with stabilization treatment, can reduce intergranular corrosion. A high-alloy steel that can resist corrosion in the air or in chemically corrosive media. Stainless steel has a beautiful surface and good corrosion resistance. It does not need to undergo surface treatment such as plating, and exerts the inherent surface properties of stainless steel. It is used in many A kind of steel, usually called stainless steel. High-alloy steels such as 13 chrome steel and 18-8 chrome-nickel steel represent performance. From the perspective of metallography, because stainless steel contains chromium, a very thin chromium film is formed on the surface. This film isolates the oxygen from the intrusion of the steel and acts as a corrosion resistance. In order to maintain the inherent corrosion resistance of stainless steel, steel must contain more than 12% chromium. Used in the occasions where welding is required, the lower carbon content minimizes the precipitation of carbides in the heat-affected zone near the weld, and the precipitation of carbides may cause stainless steel to produce intergranular corrosion in certain environments.

Using AIN ceramics for heat resistance, melt erosion and thermal shock resistance, GaAs crystal crucible, Al evaporating dish, magnetic fluid power generation device and high temperature turbine corrosion resistant parts can be fabricated, and its optical properties can be used as an infrared window. The aluminum nitride film can be made into a high frequency piezoelectric element, a very large scale integrated circuit substrate, or the like.

Aluminum nitride heat-resistant, resistant to molten metal erosion, stable to acid, but easy to be eroded in alkaline solution. The AIN fresh surface is exposed to moist air and reacts to form a very thin oxide film. By utilizing this property, it can be used as a crucible and a die-casting mold material for smelting metals such as aluminum, copper, silver, and lead. AIN ceramics have good metallization properties and can be widely used in the electronics industry as an alternative to toxic cerium oxide.

ورقة البيانات:

Ø (1) high thermal conductivity (about 320W / m · K), close to BeO and SiC, more than 5 times that of Al2O3;

Ø(2) The thermal expansion coefficient (4.5×10-6°C) is matched with Si (3.5-4×10-6°C) and GaAs (6×10-6°C);

Ø (3) excellent electrical properties (dielectric constant, dielectric loss, volume resistivity, dielectric strength);

Ø(4) good mechanical properties, higher flexural strength than Al2O3 and BeO ceramics, can be sintered at normal pressure;

Ø (5) good optical transmission characteristics;

Ø(6) non-toxic;

Application industry :

Aluminum nitride powder has high purity, small particle size and high activity, and is the main raw material for manufacturing high thermal conductivity aluminum nitride ceramic substrate.

Aluminum nitride ceramic substrate, high thermal conductivity, low expansion coefficient, high strength, high temperature resistance, chemical corrosion resistance, high resistivity, small dielectric loss, is an ideal large-scale integrated circuit heat sink substrate and packaging materials.

لماذا أخترتنا؟ 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

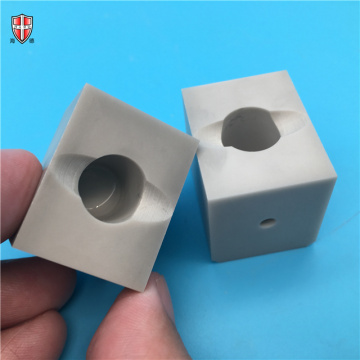

Products Show

التعليمات

س: هل أنت شركة تداول أو الشركة المصنعة؟

ج: نحن مصنع.

س: ما هي مدة وقت التسليم؟

ج: عمومًا هو 5-10 أيام إذا كانت البضائع في المخزون. or it is 15-30 days if the goods are not in stock, it is according to quantity.

س: هل تقدم عينات؟ هل هو مجاني أم إضافي؟

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

س: ما هي شروط الدفع الخاصة بك؟

ج: الدفع <= 1000usd ، 100 ٪ مقدما. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

فئة المنتج : مواد اخرى > نيتريد الألومنيوم السيراميك

(

(

مسح لزيارة

مسح لزيارة